Your cart is empty

Continue shopping

Engineering the Future of Speed

Discover the story behind Venn Cycling – a legacy of innovation in carbon wheel technology, driven by performance and precision since 2008.

From Passionate Rider to Industry Innovator

Our story began in 2008 with the founding of Velocite Bikes by Victor Major. Driven by his experience as a rider and a desire for honesty in performance claims, Velocite set out to create products that truly delivered. This foundation built on transparency and functional design paved the way for the next leap in innovation.

In 2015, Venn Cycling was launched as a dedicated R&D and manufacturing powerhouse within Velocite, specifically focused on pioneering advancements in carbon wheel technology. Our mission was clear: anchor groundbreaking manufacturing techniques, starting with our patented filament winding process, and push the boundaries of wheel performance.

Victor Major, Founder & CEO

Our Core Principles

We are driven by an unwavering commitment to performance, technology, quality, and transparency in everything we create.

Uncompromising Performance

Creating wheels that meet the demands of serious riders through superior aerodynamics, stiffness, and durability.

Technology-Driven

Continuously researching and developing new materials and processes like filament winding and AI design.

Exceptional Quality

Implementing rigorous 15-step testing and QC measures to ensure reliability and safety.

Transparency & Honesty

Providing truthful marketing and product claims, delivering on performance promises.

Our Technological Advantage

Innovation is not just a goal, it's embedded in our process. We leverage cutting-edge techniques to build superior wheels.

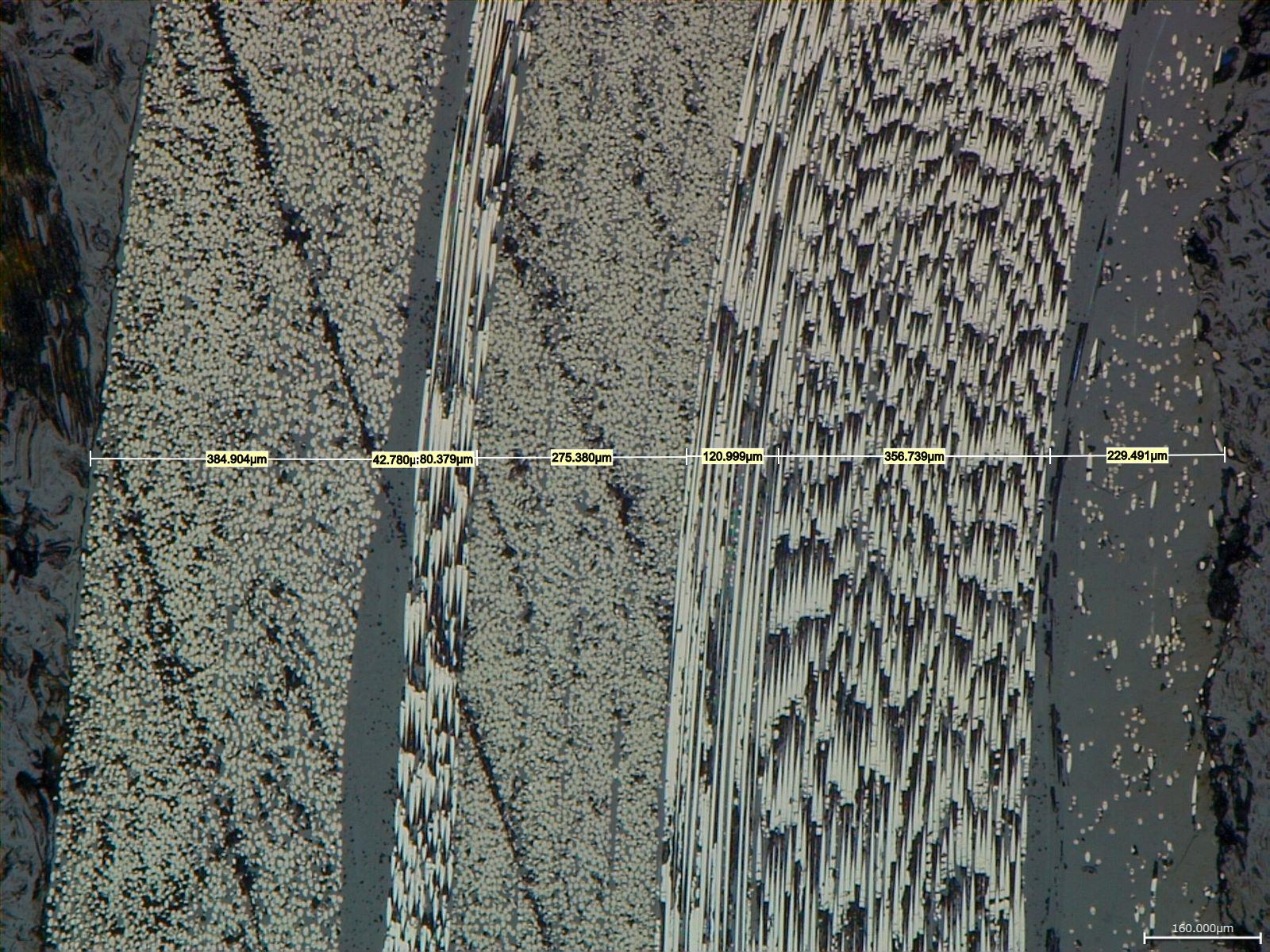

Automated Filament Winding

Our patented, computer-controlled process lays down continuous carbon fibers with unparalleled precision, ensuring optimal orientation, uniform stiffness, and exact resin content. This automated technique surpasses manual layup for consistency and performance.

Learn More

Pioneering AI Design

We embrace the future of engineering by utilizing artificial intelligence. The Venn VAR 77 rim was the world's first carbon rim developed using AI-driven aerodynamic profile design, achieving independently validated class-leading speed.

Explore AerodynamicsAdvanced Materials Science

We utilize specialized materials like 1k towpreg for precise fiber placement and superior finish. For rim brakes, our custom high-Tg resin withstands temperatures up to 240°C, preventing heat damage during prolonged braking and ensuring safety and reliability.

Discover Materials

Uncompromising Quality Control

Manufacturing excellence demands rigorous quality control. Each Venn rim undergoes no fewer than 15 distinct testing steps before sale, ensuring it meets our exacting standards and exceeds industry requirements like the UCI impact test.

- Comprehensive Testing Suite (UCI Impact, Spoke Pull-Through, Deformation, etc.).

- Heat Resistance Testing for all rim brake models.

- Proactive X-Ray Batch Testing to detect internal lamination issues.

Industry Recognition

Our commitment to innovation and quality has been consistently recognized by prestigious industry awards since our inception.

Venn Cycling, building on the award-winning legacy of Velocite, quickly made its mark:

- 2015 Taipei Cycle d&i Award (Venn Rev 35 Wheels)

- 2015 Eurobike Award (Venn Rev 35 Wheels)

- 2017 Velofollies Award (Venn Rev 35 Series)

- Part of the Velocite family, recipient of numerous awards including Eurobike, iF Design, Golden Pin, and more.

Experience the Venn Difference

Venn Cycling represents the pinnacle of carbon wheel engineering, born from a legacy of innovation and a passion for cycling. We invite you to explore our range of high-performance wheels and discover how our commitment to technology and quality can elevate your ride.