Your cart is empty

Continue shoppingAdvanced Manufacturing Process

Combining precision automation, patented technologies like filament winding, and expert craftsmanship for unparalleled quality.

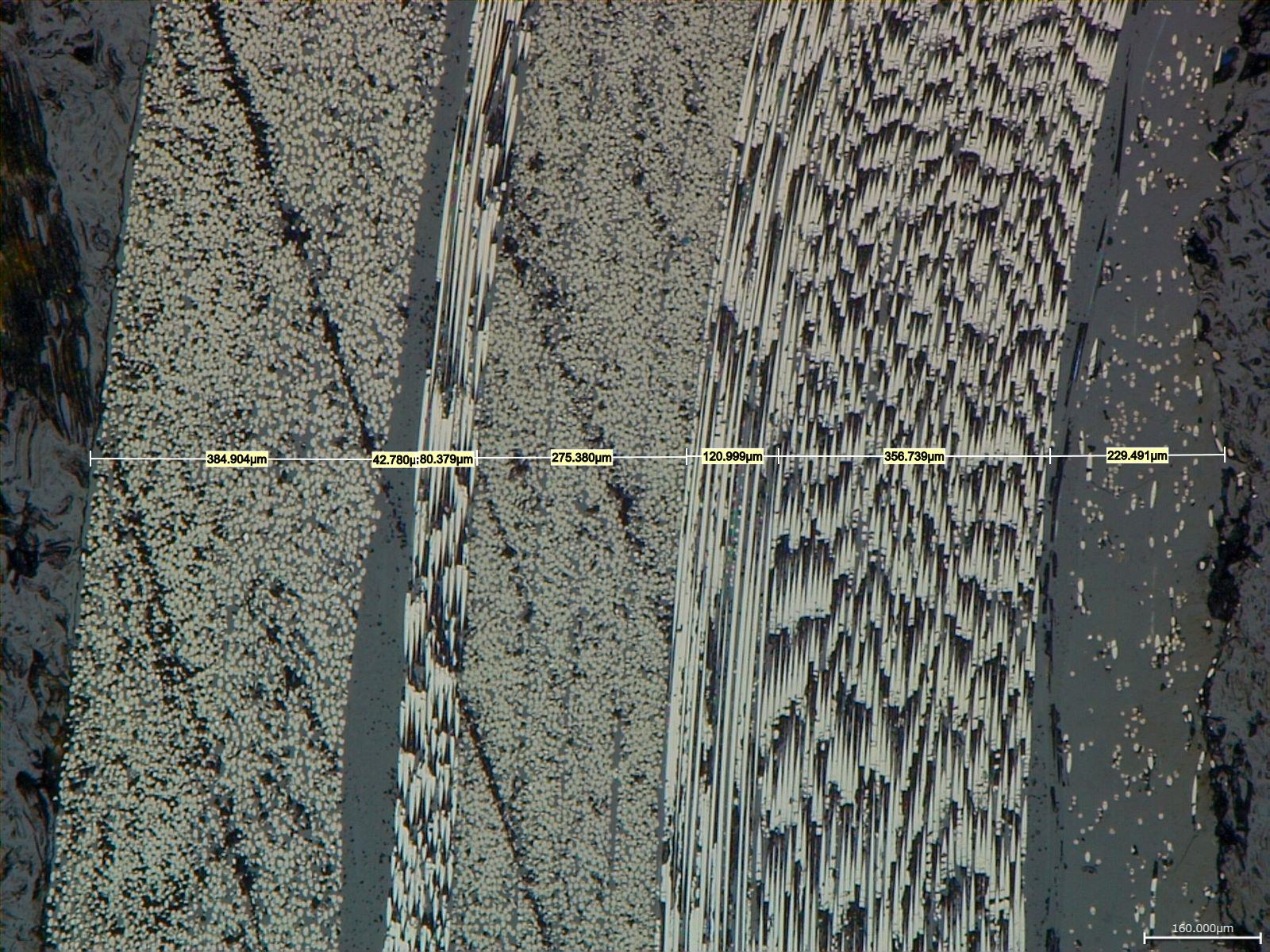

Patented Carbon Filament Winding

Our patented filament winding process ensures precise and accurate carbon fiber layup – each fiber is oriented exactly as intended by our engineers. This computer-controlled technique guarantees maximal strength and durability with uniform stiffness throughout the rim's circumference, ensuring your wheels remain true for their entire lifetime.

We utilize slit tape filament winding, which employs carbon fiber tape pre-impregnated with resin. This method delivers an exact, optimal resin content consistently across every wheel, eliminating variability and maximizing performance.

- Precise fiber orientation for optimal strength.

- Uniform stiffness for lasting wheel trueness.

- Exact resin content control via slit tape.

- Maximal durability and performance consistency.

Advanced Molding Technology

We utilize advanced compression molding technology with precise temperature and pressure control throughout the curing process. Our proprietary molding system ensures:

- Uniform resin distribution for material consistency.

- Elimination of voids and inconsistencies for structural integrity.

- Perfect fiber-to-resin ratio for optimal weight and strength.

- Consistent wall thickness for predictable performance.

Rigorous Quality Control

Every wheel undergoes multiple quality control checks throughout the manufacturing process, ensuring adherence to the highest standards.

Material Inspection

Pre-preg carbon fiber validation and batch testing.

Layup Verification

Laser projection systems ensure accurate fiber placement.

Cure Monitoring

Real-time tracking of temperature and pressure cycles.

Dimensional Inspection

Post-cure checks against precise geometric tolerances.

Surface Finish QC

Inspection for cosmetic perfection and structural integrity.

Final Assembly Check

Verification of spoke tension, trueness, and balance.

Precision Assembly

Our wheel assembly process combines precision machinery with the crucial oversight of skilled technicians:

- Automated hub lacing with integrated tension monitoring.

- Computer-controlled spoke tensioning for uniformity.

- Meticulous three-stage truing process by expert wheel builders.

- Dynamic balance testing for smooth rolling performance.

Key Manufacturing Specifications

Cure Temp. Control

± 1°C

Cure Pressure Precision

± 0.1 bar

Dimensional Tolerance

± 0.1 mm

Surface Finish (Avg.)

Ra 0.4 μm

Spoke Tension Uniformity

< 5% Variance

Wheel Trueness

< 0.2 mm (Radial/Lateral)