Your cart is empty

Continue shoppingTechnology & Engineering

Since inventing the filament winding process for manufacturing of bicycle rims in 2015, our technology stack represents more than a decade of carbon fiber innovation, advanced aerodynamic research, and rigorous engineering excellence.

Our Core Technologies

Filament Winding Manufacturing

Explore our patented, computer-controlled filament winding process for precise carbon fiber layup, ensuring uniform strength and stiffness.

Learn More →

Advanced Materials & Research

Learn about our proprietary carbon composites, high Tg resins for rim brakes, and ongoing research driving innovation.

Learn More →Aerodynamics & CFD

Discover how we use Computational Fluid Dynamics (CFD) and wind tunnel testing to achieve superior aerodynamic performance and handling.

Learn More →

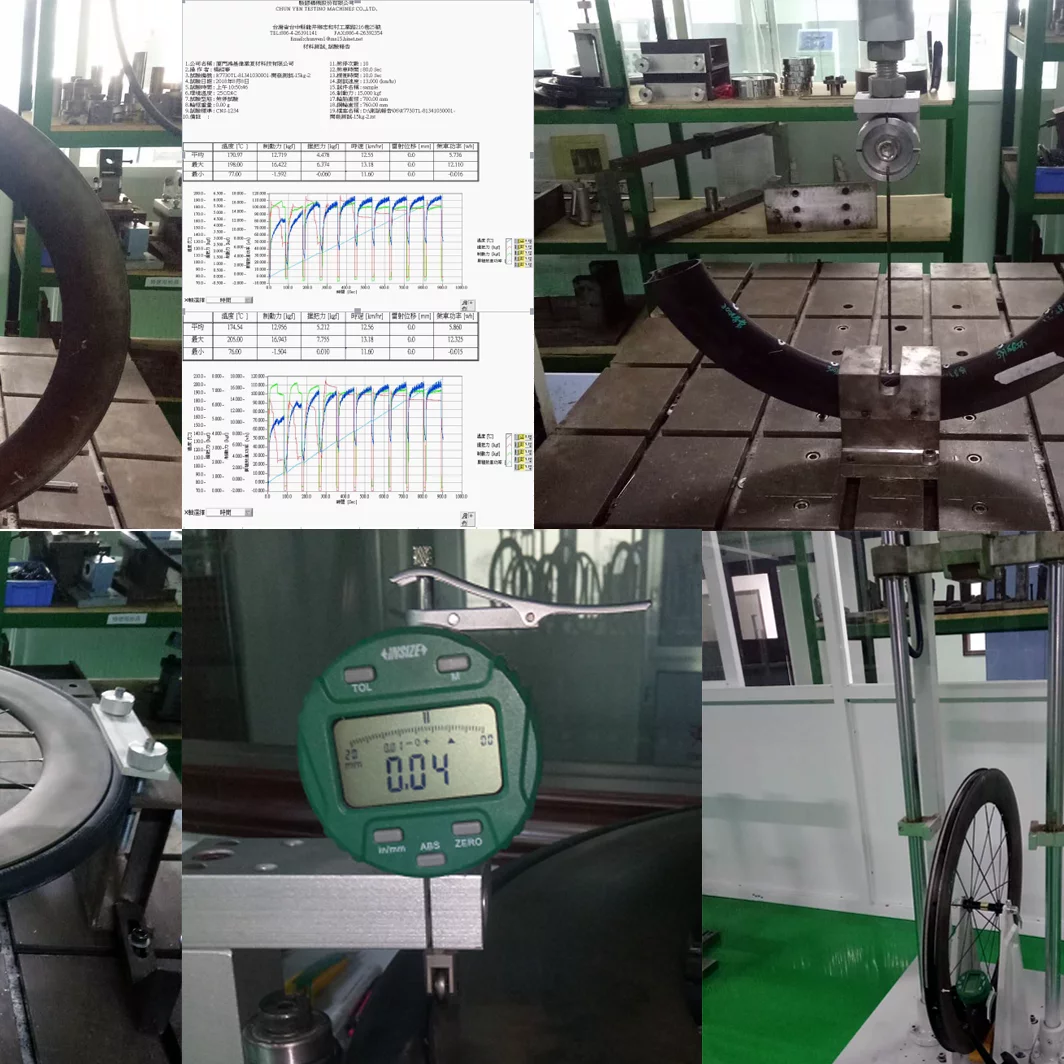

Rigorous Testing & Validation

See our exhaustive 15-step testing protocol, including UCI impact tests, ensuring every wheel meets extreme durability and safety standards.

Learn More →

Revolutionary Carbon Spokes

Our carbon spokes utilize standard 2.2mm rim holes, preserving integrity. With tensile strength exceeding steel (up to 500kgf destructive load), we use only 21 spokes for improved comfort, aerodynamics, and near-instant power transfer due to minimal yield (elongation).

- Standard 2.2mm Rim Hole Compatibility

- High Strength (500kgf Max Load)

- Reduced Spoke Count (21 Spokes)

- Enhanced Comfort, Aerodynamics & Power Transfer

Our Engineering Philosophy

Every Venn Wheels product embodies a fusion of theoretical engineering principles and practical cycling demands. Our development process integrates:

- Computational Fluid Dynamics (CFD) for world-class aerodynamic optimization.

- Finite Element Analysis (FEA) for exceptional structural integrity and durability.

- Real-world performance validation with professional athletes and demanding riders.

- Comprehensive lab testing exceeding industry standards for long-term reliability.